On a hot summer day in Texas, you experience an unexpected issue - your air conditioning system suddenly stops functioning. Upon inspection, you discover the compressor is malfunctioning. Now, you must decide on the best path forward. Should you pursue a repair of just the compressor or replace the entire AC unit? This is a difficult decision that requires many factors to consider. Key considerations include the age of the system and potential out-of-pocket costs for repair work. Good thing you're local to Leander. You call the expert AC repair in Leander, TX, Grande Air Solutions, and after inspection, we tell you whether your AC compressor is salvageable or not. But right now, without inspecting your unit, here’s the information we can offer on the internet to give you an idea:

Yes, it AC compressor is repairable in most situations. Expert HVAC professionals are the medical doctors of the air conditioning world. They have the skills and knowledge to breathe life into a non-functioning compressor and restore comfort.

It all starts with thorough diagnostics. Using state-of-the-art technology and tools, HVAC experts assess the condition and functionality of your AC unit. Just as an MRI helps doctors detect health anomalies, these diagnostics pin down correctable issues such as bad capacitors, blockage in suction lines, or even minor electrical faults.

Once you pinpoint the issue in your compressor, the repair work starts. If it's beyond repair (which usually happens in 15-20-year-old compressors), then technicians will typically advise you to replace the AC. This is because even if we fix the old AC compressor, the issues either come back or something else pops up after some time.

Besides the type of issue, there’s also the level of difficulty. The more complex an issue is, the lesser its odds are of being a 100% successful repair. Here's an example to help you understand better:

| Type of Issue | Difficulty Level / (Success Rate) |

| Bad capacitors | Low (80-85%) |

| Blocked suction lines | Moderate (60-70%) |

| Minor electrical faults | Variable (50-75%) |

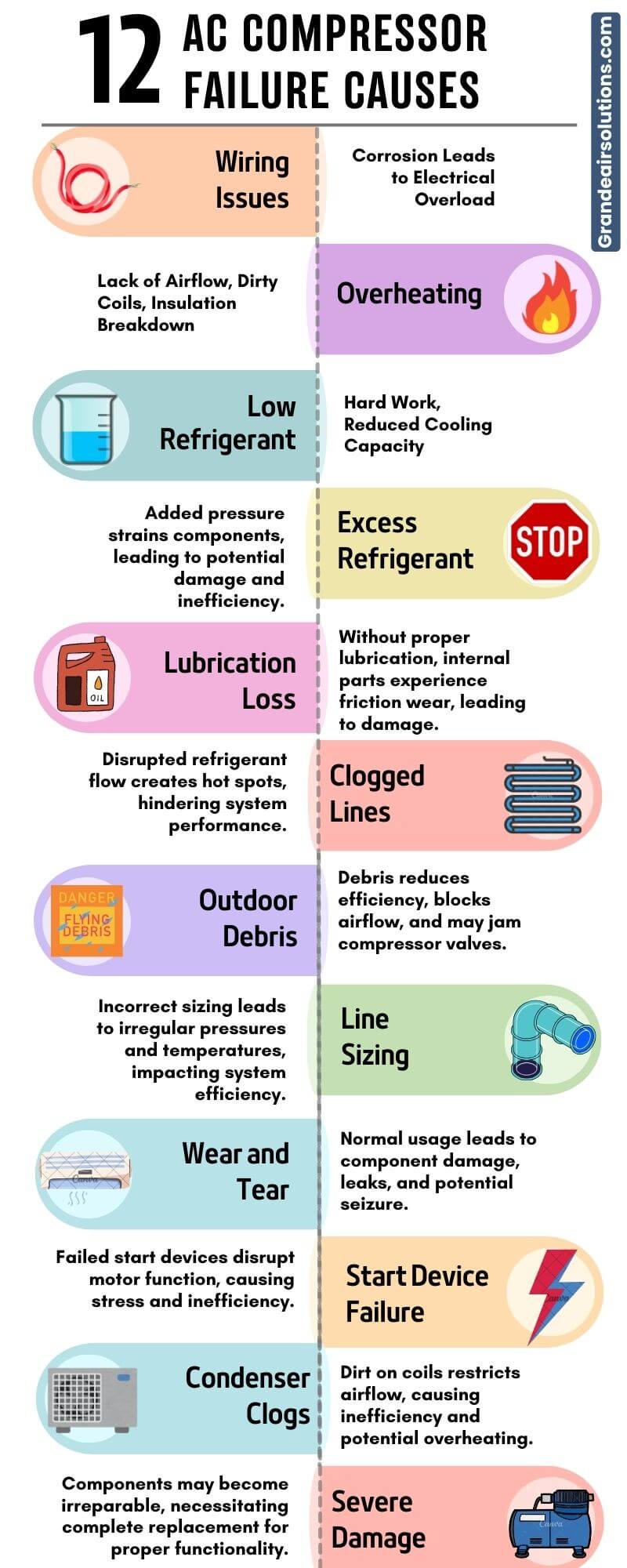

Let's take a look at some of the most common issues

When diagnosing an air conditioner with issues, one must carefully examine what could be causing the problem. A simple issue like low refrigerant can usually be fixed by recharging the refrigerant in the system. However, finding and repairing the cause of the refrigerant leak is important to prevent future problems. Extensive leaks or damage to components that cannot be easily replaced means replacing the compressor is necessary.

Worn condenser or evaporator coils may still transfer refrigerant, but efficiency suffers, so replacement is recommended if leaks cannot be repaired. Internal damage within the compressor, such as faults with the pistons, bearings, or valves, requires a full rebuild or replacement of the compressor altogether.

Acquiring the necessary parts to repair an air conditioner is crucial in determining if repair is possible. Older units, especially those over 20 years old, frequently have limited or no parts support, as manufacturers usually only maintain part inventories for 10 to 15 years. Rebuild kits allow one to repair the existing compressor housing, but the internal wear parts, such as pistons or valves, still need to match the specifications.

Generic replacement compressors may fit physically, but performance gains from an engineered original equipment manufacturer match cannot be guaranteed. The availability of electrical, refrigerant, and mounting adaptations also influences the practicality of any replacement option.

Having hands-on experience working on a particular air conditioner model helps technicians understand common failure modes and issues to watch out for in specific designs. Troubleshooting skills gained from experience avoid unnecessary part changes.

Manufacturer training provides technicians with intended repair methods, special tools, and assembly/charging techniques. Working on an unfamiliar unit for the first time takes more diagnosis time and risks overlooking a recurring problem known to others.

Properly documenting previous similar jobs aids future repairs in case of personnel changes.

Most home system warranties will cover replacing defective components for the warranty duration, usually 5-10 years, but may decline to pay labor costs for repair work like rebuilding or fixing the compressor.

Non-warranty owners must weigh the costs of repair versus replacement and consider the risk of further failures in a repaired unit.

Air conditioners and heat pumps over 15 years old frequently use the more expensive R-22 refrigerant and have lower SEER efficiency ratings. As they age, finding replacement parts gets more difficult due to declining inventories.

Labor costs for complicated repairs easily exceed a new high-efficiency unit's purchase and installation fees. Major components like compressors typically last around 15 years on average.

| Issue | Effect on Repairability |

| Low Refrigerant | Usually repairable by recharging refrigerant |

| Minor Leak | Repairable if the leak is found and sealed |

| Condenser coil damage | Repairable if coils can be repaired or replaced |

| Compressor internal damage | Often requires compressor rebuild or replacement |

| Extensive corrosion | Increased difficulty of repairs and reduced component life |

The compressor comprises of several small complex parts that move in perfect synchronization during operation.

Over years of this continuous operation, friction, and vibration gradually wear down these components, reducing efficiency.

Technicians disassemble the entire compressor housing during a rebuild using specialized extraction tools. They clean these parts carefully and inspect them under bright lighting.

They use micrometers to precisely measure wall thicknesses and diameters and ISO tolerances to assess the wear. If they find damage to any parts beyond repair, they work on replacement.

Plastic shaft seals and rubber gaskets exhibit cracks and breaks after heavy use. Metallic valves and piston rings exhibit grooves and decreased clearances. Replacement parts are identical OEM or high-quality aftermarket equivalents.

The compressor motor is a complex electro-mechanical device. Its startup component, the start capacitor, faces especially high electrical stresses during each hot and cold cycle. The winding insulations deteriorate over 10-20 years from heat and chemical breakdown. The capacitance decreases below necessary torque levels.

Electronic tests diagnose failure mechanisms like shorted, open, or low microfarad windings during repair. In some cases, experienced technicians can carefully rewind the coils and replace damaged sections.

More often, non-repairable failures require the installation of new capacitors matched to compressor specs. Run capacitors warrant similar testing and replacement protocols since a faulty component can strain other systems. Proper new OEM capacitors rejuvenate motor performance.

Low refrigerant is one of the most common issues encountered, as copper and brass components gradually develop microscopic leaks over time. Even small amounts escaping each year can lead to inadequate system charging.

During repair, technicians utilize manifolds, hoses, gauges, and weighing scales to conduct thorough leak testing. Digital pressure sensors pinpoint leak locations that require sealing.

The refrigerant charge amount is critical for efficient heat transfer and oil return. Too much or too little negatively impacts temperatures, pressures, and wear rates. Using thermodynamic charts and system specs, technicians calculate precise recharge amounts of virgin refrigerant by weight, not volume, which varies based on temperature.

Recharging is done meticulously in multiple small stages to prevent introducing air bubbles or liquid into components. Infrared cameras verify uniform superheat and subcooling across the entire circuitry.

Modern HVAC systems move thousands of pounds of air per hour, pulling in dust, pollen, and other allergens that obstruct airflow over time. Inside compressors, this accumulates into a thick sludge.

During disassembly, technicians inspect for corrosion from moisture and chemicals. All ferrous metal parts like coils and tubes undergo chemical baths and ultrasonic agitation to dissolve away carbon deposits and oxidization.

Compressed air blows out residual debris from tight tolerances without damage. Vacuuming thoroughly dries parts to prevent new rust issues. Cleaning restores heat transfer surfaces and unblocks critical flow passages.

Microscopic video borescopes inspect interior assemblies for remaining particles that can prematurely wear moving components if not removed. A system's full efficiency and longevity can be restored only through this deep cleaning.

Compressor overhaul kits provide a precisely engineered set of new internal parts designed to function as an integrated system. Each component, like piston rings, valves, and shaft seals, is manufactured to tight tolerances that maintain balanced compression and oil control.

Technicians meticulously inspect overhaul kit contents to verify all necessary pieces are included according to the compressor data tag. Replacement of old components follows a careful process. Piston rings and valves are delicately pried out without damage, and new ones are compressed in with specialty tools.

The valve plate and valve port surfaces are lapped to a mirrored finish to prevent leakage. Shaft seals and gaskets are formulated from specialized elastomers that maintain flexibility under high pressures and temperatures for the lifespan of the rebuild.

Proper lubrication is also critical, as compressors utilize specialized thickened oils. The correct viscosity and additive package prevent wear between moving metal surfaces while maintaining an insulating film. Overhauled compressors undergo performance verification cycling to ensure smooth synchronous motion before being charged and installed. Kits enable complex rebuilds to restore like-new efficiency and reliability.

Vibration isolation mounts are engineered to last the lifetime of a properly functioning compressor under normal loads. However, deteriorated brackets have been known to crack or deform over time due to compressor faults that cause excessive shaking.

Technicians carefully inspect all structural attachment points for signs of fatigue, such as hairline fractures, bending, or loosening bolts. To avoid catastrophic failures, failed brackets must be replaced. Precision-machined mounts made from corrosion-resistant steel alloys pair compressor vibration characteristics with the structural characteristics of the unit frame.

Proper torque sequencing compresses mount to their designed stiffness while avoiding excess stresses on internal components. Reinstallation prevents future issues by securely affixing the compressor to its engineered position.

Unfortunately, in some circumstances, no amount of work or part replacement can restore an AC compressor.

A seized or fractured crankshaft renders all connected components ineffective. The motor cannot drive pistons up and down to do work without the integrity of this crucial axial component.

Sometimes, metal shards must be carefully removed to inspect the full extent of seized areas, necessitating replacement.

If electrical insulation breaks down, allowing windings to touch, severe overheating can alter coil shapes and melt adjoining metals.

Smokey burn scents indicate past overloads, and testing locates shorts. The compressor motor converts but fails to drive refrigeration processes without a stable magnetic field.

While rebuild kits restore tolerances, deteriorated specifications like borehole diameters may exceed safe thresholds. Sustained operation with compromised clearances hastens breakdown.

Air conditioning sizing calculations rely on original manufacturer performance ratings, requiring a new unit if prior wear drops capacity too far.

Some uncommon failures escapeidentification even after a complete disassembly. Troubleshooting then turns to replacement rather than risky repairs.

Unresolved issues may reoccur, so proper identification remains important before putting a system back together.

At a certain point, labor fees and parts costs eating into the economic lifespan make repairs unrealistic.

While preserving existing fittings, new equipment proves more cost-effective than rebuilding aged parts. Installation completes the upgrades economically.

As environmental standards tighten, older ozone-depleting refrigerants face regulations. Recharging becomes impossible without adapted recovery/recycling equipment. Replacement remains the sole feasible solution for continuing operations.

| Issue | Reason Beyond Repair |

| Seized piston | Cannot move to compress refrigerant |

| Melted wiring | Electrical failure risks further damage |

| Cracked housing | Refrigerant escape cannot be stopped |

| Missing internal parts | Performance cannot be restored |

| Diagnosis fails to find root cause | The issue may reoccur after repair |

| Refrigerant phase-out | The system cannot be recharged |

The technicians at Grande Air Solutions are highly trained and experienced in diagnosing AC compressor issues. Our expertise can help determine whether repair or replacement is recommended.

For AC repair Leander, TX, trust the pros at Grande Air Solutions. Our team provides quality AC compressor inspection, installation, and AC repair in Leander, TX you can rely on.