According to the U.S. Energy Information, HVAC systems account for approximately 48% of a typical home's energy consumption in the southern United States. For homeowners seeking HVAC services in Austin, where temperatures regularly soar past 100°F in summer, proper maintenance isn't just about comfort—it's essential for energy efficiency and system longevity.

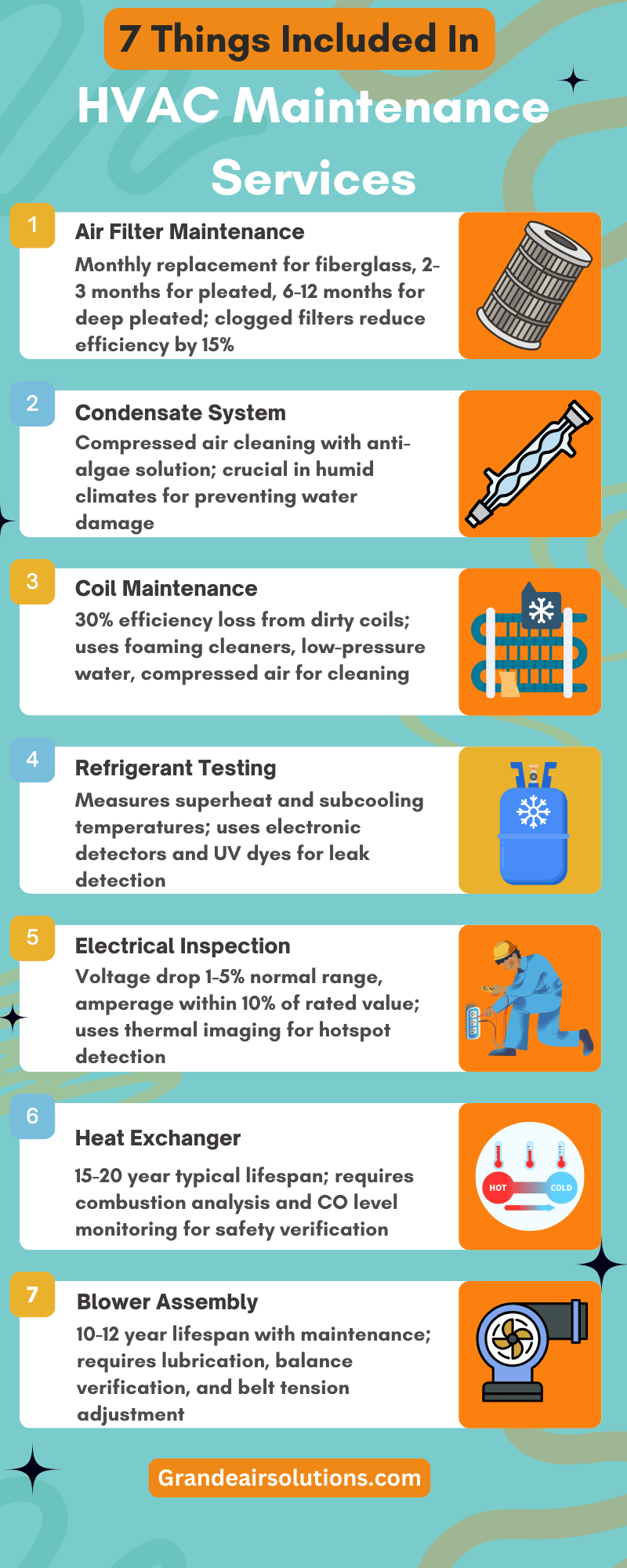

Regular air filter maintenance stands as a cornerstone of HVAC system health. This simple yet crucial task impacts everything from energy bills to indoor air quality. Here are some filter types to know first:

Filter Type | Replacement Schedule |

Fiberglass | Monthly |

Pleated Cotton/Polyester | Every 2-3 months |

Deep Pleated | Every 6-12 months |

Your HVAC system will tell you it needs a filter change through several signs. Watch for reduced airflow from your vents or unusual dust accumulation in your home. These indicators often appear before more serious problems develop.

The MERV rating helps you choose the right filter for your needs. Think of it as a report card on your filter's ability to catch different-sized particles.

Particle Size Range | Common Examples | Filtration Notes |

0.001-0.003 μm | Molecules, Small Virus Particles | Captured by HEPA filters through diffusion |

0.003-0.1 μm | Viruses, Carbon Black, Atmospheric Dust | Captured by HEPA/ULPA filters through diffusion and interception |

0.1-0.3 μm | Vehicle Emissions, Metal Fumes, Virus Clusters | Captured by higher MERV (13-16) and HEPA filters |

0.3-1.0 μm | Bacteria, Tobacco Smoke, Smog, Cooking Smoke, Most Bacteria, Oil Smoke | HEPA's MPPS range (99.97% efficiency), MERV 11-16 effective |

1.0-3.0 μm | Mold Spores, Pet Dander, Fine Dust, Hair Cell Fragments, Insecticide Dust, Coal Dust | Effectively captured by MERV 8-16 filters |

3.0-10.0 μm | Dust Mites, Pollen, Plant Spores, Textile/Carpet Fibers, Hair Spray, Cement Dust, Lint | Captured by most filters MERV 6 and above |

10.0-100.0 μm | Visible Dust, Sand, Human Hair, Large Plant Matter, Paint Pigments | Captured by basic filters, visible to the naked eye |

Notes:

Did you know a clogged filter forces your system to work 15% harder? This extra strain translates directly to higher energy costs. You'll find that regular filter changes pay for themselves through improved efficiency and system longevity.

Austin's climate poses unique challenges for HVAC filters. Our hot summers mean more system runtime, while cedar fever season demands extra attention to filtration. You might need more frequent changes during these peak periods.

Your HVAC system relies on two essential components: the evaporator and condenser coils. These coils work together, handling the critical task of heat exchange. Understanding their maintenance helps you appreciate why regular cleaning matters so much.

The evaporator coil inside the home absorbs heat from indoor air. The condenser coil in the outdoor unit releases this heat outside. This continuous cycle keeps your home comfortable throughout Austin's challenging weather conditions.

Coil Type | Primary Function |

Evaporator Coil | Absorbs indoor heat, cools air |

Condenser Coil | Releases heat outdoors |

Your system sends clear signals when coils need cleaning. You might notice longer cooling cycles or higher electricity bills. Even a thin dirt layer can reduce efficiency by up to 30%.

Warning Sign | What It Means |

Warm Air From Vents | Reduced Heat Transfer |

Higher Energy Bills | System Working Harder |

Ice Formation | Restricted Heat Exchange |

In Austin's climate, your outdoor condenser coil faces unique challenges. Live oak pollen in spring and cottonwood fluff in early summer can quickly clog these vital components.

Refrigerant is the lifeblood of your HVAC system. It doesn't consume refrigerant like a car uses gas but continuously cycles this fluid through the system. Any drop in refrigerant levels indicates a leak that needs immediate attention.

Warning Signs of Incorrect Refrigerant Levels

Test Type | Purpose |

Superheat Testing | Ensures proper evaporator coil operation |

Subcooling Testing | Verifies condenser coil effectiveness |

Technicians use specialized gauges to measure these critical temperatures. These readings help identify the exact amount of refrigerant needed. These experts understand the complex relationship between pressure and temperature. Their knowledge prevents dangerous system conditions that could damage your compressor. Austin's hot climate demands precise refrigerant levels for optimal cooling performance.

Modern systems use newer refrigerants that protect the environment. Your technician ensures compliance with current regulations while maintaining your system. They'll check for leaks using electronic detectors and UV dyes.

Professional technicians carefully examine each electrical part to ensure safe and efficient operation. Regular electrical inspections help prevent unexpected breakdowns and safety hazards.

Component | Function |

Capacitors | Store energy for motor startup |

Contactors | Control power flow to components |

Circuit Boards | Manage system operations |

Technicians use specialized multimeters to measure electrical values. These precise instruments detect issues before they cause a system failure. Austin's extreme summer heat puts extra stress on electrical components.

Test Type | Normal Range |

Voltage Drop | |

Amperage Draw | Within 10% of the rated value |

Your technician follows strict safety protocols during electrical inspections. They power down the system completely before accessing any components. This protects both the equipment and the service professional.

Thermal imaging cameras help identify hot spots in electrical connections. These advanced tools detect potential problems invisible to the naked eye. Early detection prevents costly emergency repairs and safety hazards.

Austin's weather creates unique challenges for electrical components. High humidity leads to faster corrosion of electrical contacts. Your technician applies special protectants to guard against moisture damage.

Most electrical problems have early warning signs. When your system starts up, you might notice dimming lights. Strange noises or burning smells indicate electrical issues requiring immediate attention.

Professional evaluation includes checking for code compliance. Updated safety standards may require modifications to older systems. Your technician ensures your system meets current electrical safety requirements.

Your HVAC system's condensate drain removes excess moisture generated during cooling. A properly functioning condensate drain prevents several serious issues affecting your HVAC system and home structure. Technicians inspect your system and ensure this vital component operates at peak efficiency.

Here's what HVAC professionals examine during a condensate drain service:

Inspection Point | Purpose |

Drain Line Flow | Ensures water moves freely without backup |

Drain Pan Condition | Checks for rust or damage that could cause leaks |

P-Trap Status | Verifies proper water seal maintenance |

During inspection, technicians look for these specific issues:

The cleaning process involves several steps that ensure thorough maintenance. First, technicians use compressed air to clear any existing blockages. They then apply specialized cleaning solutions that remove buildup and prevent future growth of algae.

This maintenance has significant benefits for your system. You'll notice improved air quality, better humidity control, and reduced risk of water damage. Regular cleaning also extends your HVAC system's lifespan by preventing strain from poor drainage.

Austin's humid climate makes condensate drain maintenance particularly important. The region's weather conditions can accelerate algae growth and increase the condensation your system produces, so local homeowners should pay special attention to this aspect of HVAC maintenance.

You need a properly functioning blower to maintain comfort in your Austin home. HVAC technicians examine this component thoroughly during maintenance visits to prevent future issues.

Component | Maintenance Required |

Blower Motor | Lubrication and bearing check |

Blower Wheel | Cleaning and balance verification |

Drive Belt | Tension adjustment and wear inspection |

Your HVAC technician will check the motor bearings for signs of damage and listen for unusual noises that might indicate potential problems. The blower wheel will also be thoroughly cleaned to remove built-up dirt and debris. This step helps maintain proper air balance and distribution throughout your home.

A well-maintained blower assembly can easily last 10-12 years or more. Without proper care, however, replacements might be needed much sooner.

Heat exchanger inspection is one of the most crucial safety checks during HVAC maintenance. This component separates combustion gases from your home's breathing air, and its condition directly affects your family's safety.

Your technician will perform a comprehensive combustion analysis. This test measures how efficiently your system burns fuel. They also check carbon monoxide levels to ensure your safety. A properly functioning heat exchanger should show no traces of carbon monoxide in your home's air.

If problems appear, immediate replacement becomes necessary. With proper maintenance, heat exchangers typically last 15-20 years. However, factors like high humidity and frequent use can shorten their lifespan in Austin's climate.

Understanding when your HVAC system needs service helps prevent major breakdowns and expensive repairs. Your system communicates its needs through various signs that technicians can interpret. Let's explore these indicators in detail to help you make informed decisions about maintenance timing.

Your energy bills serve as an early warning system for HVAC issues. When you notice a sudden spike exceeding 10% without changing your usage patterns, your system likely needs attention. Think of it like your car's fuel efficiency dropping unexpectedly - something isn't working as it should.

Warning Sign | When to Call the Service |

Temperature Fluctuation | Beyond ±2°F from setting |

Running Time | Cycles longer than 20 minutes |

Your HVAC system should operate quietly and efficiently. When you start hearing unusual noises, it's similar to how a car makes different sounds when something isn't right. A properly functioning system produces a steady, gentle hum. Clicking sounds might indicate electrical issues, while banging often suggests loose components.

Airflow problems deserve immediate attention. Your system should deliver approximately 400 CFM of air per ton of cooling capacity. When airflow drops below this level, your system works harder and costs more. You might notice rooms taking longer to reach comfortable temperatures.

Physical signs often provide the clearest indicators of HVAC problems. Ice formation on refrigerant lines indicates incorrect pressure levels or refrigerant issues. Water leaks near your indoor unit might signal a blocked condensate drain. These visible signs typically mean your system needs professional attention soon.

Remember that promptly addressing these signs results in simpler, less expensive repairs. Waiting until your system fails often leads to more extensive and costly solutions. Regular maintenance visits can catch many of these issues before they develop into serious problems.

Austin's extended cooling season (March through October) demands careful HVAC maintenance scheduling. With temperatures frequently exceeding 100°F for 5-6 weeks annually, your system faces significant stress that requires regular professional attention.

Service Type | Recommended Frequency |

Basic Maintenance | Twice yearly (Feb/Mar and Oct/Nov) |

Filter Changes | Every 30-45 days |

The baseline recommendation includes two yearly maintenance visits for cooling system preparation in February/March and heating system readiness in October/November. Austin's high humidity levels (65-70%) require monthly condensate line inspections during the cooling season to prevent water damage and maintain efficiency.

System age dictates service frequency:

Heavy usage (over 12 hours daily) or location near construction zones may necessitate additional maintenance to maintain optimal performance.

Technical maintenance follows specific intervals: yearly coil cleaning, quarterly refrigerant checks during summer, and electrical component testing every six months. These become increasingly critical as systems age or face heavy use during Austin's intense cooling season. Homes experiencing high dust exposure or elevated pollen counts often require more frequent filter changes and coil cleaning..

With skilled technicians, transparent pricing, and same-day service availability, Grande Air Solutions brings top-tier HVAC expertise to Austin residents.

Join our Grande Club Membership for just $240 and enjoy exclusive benefits, including extended parts and labor warranty, priority 24-hour service, 10% off repairs, and two seasonal maintenance with no overtime charges.

Don't wait until your system fails – schedule your service today at (512) 677-4424, or take advantage of our limited-time AC maintenance special for just $69.99. Your comfort is our priority, and we service all major brands.